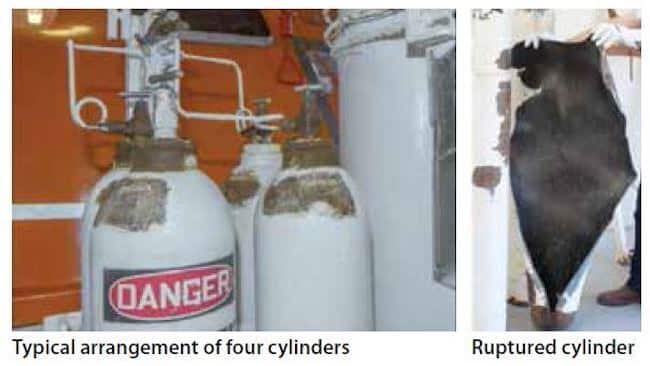

Connections were checked but no leaks were found. It was decided to change the pneumatic distribution block (manifold) to fix the situation. The system was brought to ambient pressure according to the procedure. The manifold was changed and the crew began to re-pressurise the system, again as per procedure. Without warning, one of the cylinders ruptured, sending shrapnel and debris flying. The event fatally wounded one of the nearby crew members.

To date, the official investigation has discovered that:

- The burst cylinder had become severely corroded on the exterior, reducing the cylinder wall thickness by 75% at the point of rupture.

- Several other cylinders on board the vessel were found to be exhibiting similar levels of exterior corrosion.

- The current inspection regime for such cylinders may not be adequate to detect unsafe cylinders.

Lessons learned

- Although the cylinders were inspected annually, the surface rust does not seem to have raised suspicions about the structural integrity of the units. Cylinder wall thickness measurements may be a necessary step to control risks.

Reference: nautinst.org